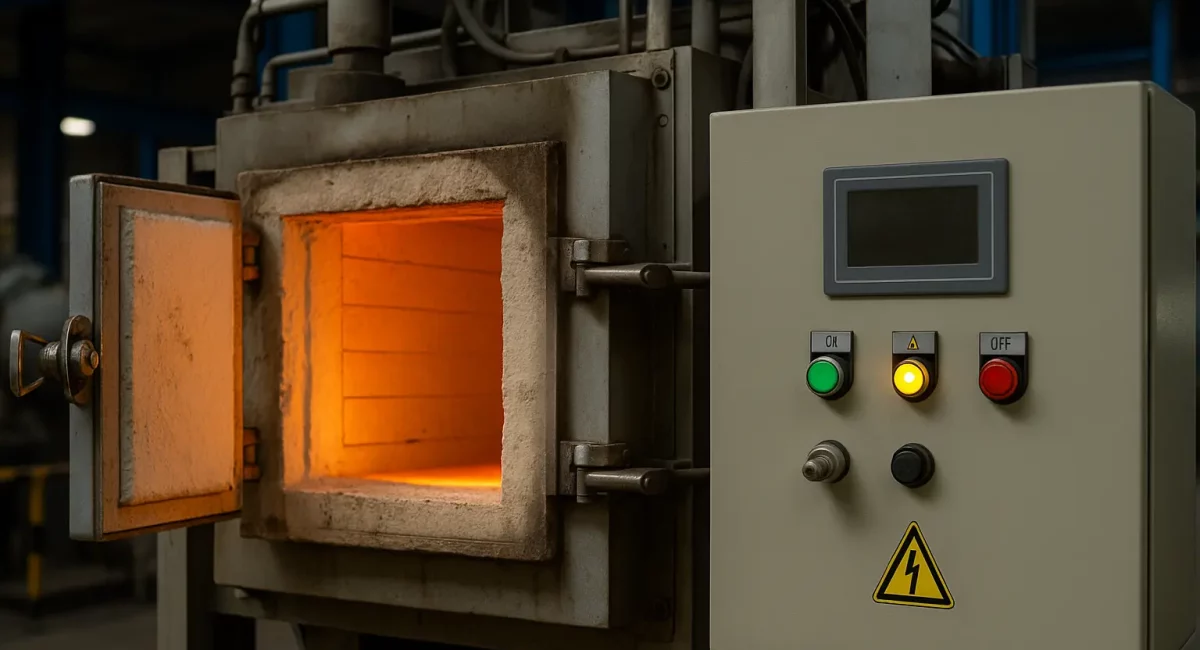

In industrial environments where extreme temperatures and high-volume production are routine, the design of a furnace isn’t just about performance—it’s about ensuring long-term maintenance efficiency and operator safety. While manufacturers often focus on output and energy efficiency, overlooking critical aspects of furnace design can lead to costly downtime, frequent repairs, and even safety hazards.

At the forefront of safe and reliable thermal systems is Precons Furnaces, a company renowned for engineering precision-based custom furnaces that seamlessly integrate durability, ease of maintenance, and operator protection into every unit.

Furnace Design: The Hidden Factor Behind Downtime

Every element in a furnace’s architecture—from insulation layout to burner positioning—directly affects how easy or difficult it is to maintain. A poorly designed system often necessitates extended shutdowns for part replacements or inspections, resulting in production losses.

Key Design Elements That Influence Maintenance:

Modular Component Design

Furnaces built with modular assemblable, low-maintenance teams to replace individual parts, such as heating elements, burners, or fans, without dismantling the entire unit.

Access Panels and Service Ports

Precons Furnaces integrates intelligently placed service hatches, enabling technicians to quickly inspect, clean, or repair components, thereby significantly reducing downtime.

Thermal Insulation and Refractory Materials

Durable lining reduces wear from repeated heating cycles, minimising the need for replacement and reducing safety risks associated with exposed hot zones.

Standardization of Parts

Using globally available, standardized parts ensures that replacements are quick and affordable—no waiting weeks for custom spares.

The Safety Equation: Where Design Meets Risk Management

A furnace operates under extreme thermal stress and can pose several safety hazards, including radiant heat, explosive atmospheres, mechanical burns, and even structural failure.

That’s why safety-oriented design is a non-negotiable priority for manufacturers like Precons Furnaces.

Design Features That Enhance Operator Safety:

Double-Walled Chamber Construction

Reduces surface temperatures and prevents accidental burns or heat exposure to nearby workers.

Emergency Shutoff & Fail-Safe Systems

Integrated into the PLC/SCADA systems, these allow quick furnace isolation in the event of sensor failure or process deviation.

Ergonomic Load/Unload Zones

With its reduced loading height and smooth roller guides, Precons ensures minimal strain and a reduced risk of injury during batch handling.

Overpressure and Flame Monitoring Controls

Precons integrates sensors that constantly monitor gas pressure, flame stability, and airflow, triggering alarms or shutdowns if anomalies are detected.

Explosion-Resistant Designs for Atmosphere Furnaces

Especially in sealed quench or gas nitriding units, special vents and blast panels are included to avoid structural damage during overpressure events.

Why Precons Furnaces Sets the Benchmark

With over 25 years in thermal engineering, Precons Furnaces leads with a design-first mindset. Their systems aren’t just built to run—they’re built to run longer, safer, and smarter. Each project includes:

- Finite element analysis (FEA) to test thermal stress points

- Custom automation with interlock-based safety features

- Easy-to-maintain layout with colour-coded piping and modular frames

- Built-in training and documentation for in-house maintenance teams

Precons’ Commitment to Safety-Driven Design

For industries that demand precision and consistency, product reliability begins with dependable heat treatment, and that starts with a well-engineered furnace. Precons Furnaces specialises in custom-designed batch systems that align with the highest safety and maintenance standards. These solutions are built to minimise downtime, reduce operational risks, and extend equipment life, making them ideal for high-performance manufacturing environments.

Conclusion

Whether you’re in aerospace, automotive, or tool manufacturing, your furnace design will have a direct impact on maintenance costs and safety performance. It’s not enough to choose a high-output furnace—you need one that’s easy to service, safe to operate, and designed with the future in mind.

With Precons Furnaces, you’re investing in more than a machine—you’re securing long-term operational reliability and workforce protection.

Seeking a furnace designed for safety and reliability? Contact Precons Furnaces for custom solutions that minimise risk and ensure uninterrupted production.