The effects of climate change are one of the most pressing problems facing our planet. The combustion of fossil fuels and the emission of greenhouse gases have warmed the earth’s atmosphere, resulting in extreme weather, rising sea levels, and the destruction of ecosystems. The utilization of neutral steel is one approach that has the potential to resolve this issue.

Neutral Steel

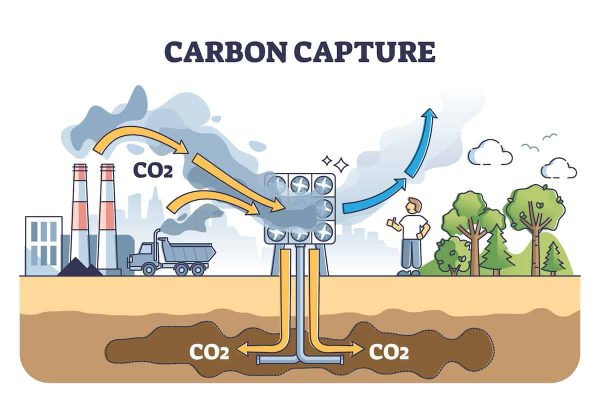

Neutral steel is a type of steel that is produced using carbon capture and storage technology. This process captures the carbon dioxide emissions generated during steel production and stores them underground. By capturing and storing carbon emissions, neutral steel production significantly reduces the number of greenhouse gases released into the atmosphere. It is estimated that neutral steel could reduce greenhouse gas emissions by up to 90%.

Environmental Impact of Neutral Steel:

- The environmental impact of neutral steel is a complex issue, as it depends on the specific technology and processes used in its production. However, in general, the utilization of neutral steel can have a beneficial effect on the environment by lowering the number of greenhouse gases that are discharged into the atmosphere.

- Carbon Capture and Storage (CCS) technology is the key element in neutral steel production. This technology captures and stores carbon dioxide emissions generated during steel production, preventing them from being released into the atmosphere. The production of neutral steel can help to slow down the warming of the earth’s atmosphere and mitigate the effects of climate change, such as rising sea levels, extreme weather events, and the destruction of ecosystems. This is accomplished by reducing the number of greenhouse gases that are released during the production process.

- CCS technology is still in the preliminary stages of its development. It must undergo additional development to achieve greater levels of productivity and cost-effectiveness. Additionally, the infrastructure for carbon capture and storage needs to be developed and implemented on a large scale to reduce greenhouse gas emissions significantly.

- Another important aspect of environmental impact is the lifecycle of the steel product. Getting the raw materials and energy needed to make steel can affect the environment and society. Therefore, it’s crucial to consider the environmental impact of the entire lifecycle of the steel product, not just the production process.

- The recycling of steel products is an important consideration to take into account. Steel is one of the highest recycled commodities in the world, and recycling it results in a big decrease in the quantity of energy and other resources necessary for its manufacture. Therefore, it’s essential to promote and encourage the recycling of steel products to minimize the overall environmental impact of steel production.

Applications of Neutral Steel:

One of the major advantages of neutral steel is that it can be used in a wide range of applications. From construction and infrastructure to transportation and energy production, neutral steel can significantly reduce carbon emissions in many industries.

For example, using neutral steel to produce buildings and bridges in the construction industry can significantly reduce their carbon footprint. Similarly, in the transportation industry, using neutral steel to produce cars and trains can help reduce their emissions.

Cost-Effectiveness of Neutral Steel:

Another advantage of neutral steel is that it is a cost-effective solution to climate change. The cost of producing neutral steel is similar to traditional steel production, making it an accessible solution for both small and large industries.

Furthermore, as the demand for neutral steel increases, economies of scale can be achieved, which can help to reduce the cost of production further.

Limitations of Neutral Steel:

Carbon-neutral steel is not a solution to the problem of climate change. It is just one of the many potential solutions that must be implemented to successfully solve the issue at hand. Additionally, the carbon capture and storage technology used in neutral steel production is still in the early stages of development and needs further improvement to become more efficient and cost-effective.

The infrastructure for carbon capture and storage needs to be developed and implemented on a large scale to reduce greenhouse gas emissions significantly. Also, it’s important not to forget that neutral steel is still a product of extracting and processing raw materials and energy inputs which can have environmental and social impacts.

Conclusion:

In conclusion, neutral steel is a promising solution to climate change. Its ability to significantly reduce greenhouse gas emissions, its wide range of applications, and its cost-effectiveness make it an attractive option for addressing the problem. Neutral steel is not a silver bullet and must be implemented alongside other solutions to address climate change effectively.

Additionally, the CCS technology used in neutral steel production need to be further improved and implemented on a large scale to make a significant impact. It’s important to consider the holistic approach to address climate change, and neutral steel is one of the many options at our disposal.

‘Precons Furnaces‘ is still exploring what plate distribution looks like in a carbon-neutral supply chain. As demand for green steel grows, we expect to see many evolutions in our industry, which is why our team of experts collaborates with mills and customers alike to expand our product.

» Contact us right away if you want to find out more about our products or get a quote.

» Follow our Social Media pages for recent updates. Facebook | Instagram