In pursuing a greener and more sustainable world, industries constantly seek innovative solutions to reduce their environmental footprint. The rotary tube furnace is a remarkable technology making significant strides. This versatile and highly efficient furnace is pivotal in various industrial processes, contributing significantly to environmental sustainability. This comprehensive article delves into how rotary tube furnaces drive positive change for businesses and the environment.

Rotary Tube Furnace

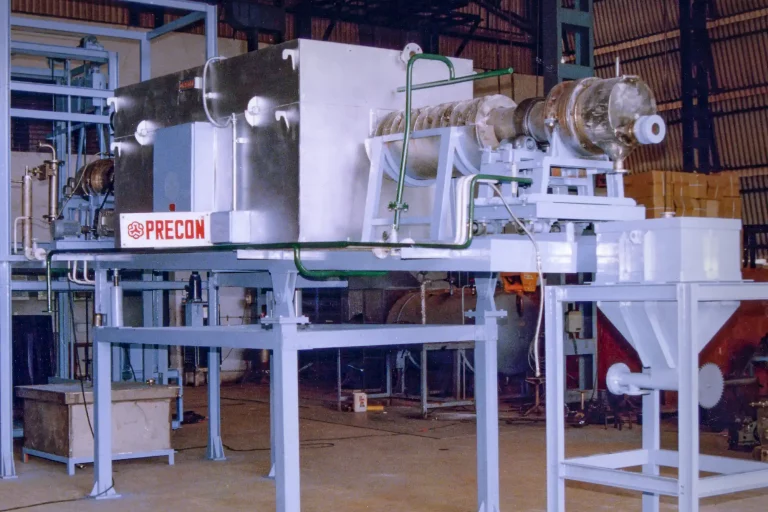

Before exploring the environmental benefits, let’s begin with a brief overview of a rotary tube furnace and its functions. A rotary tube furnace is a specialized equipment used in industries such as metallurgy, ceramics, and chemical processing. Its primary function is to heat materials to high temperatures in a controlled environment.

How Rotary Tube Furnaces Work

It consist of a long, cylindrical tube that rotates around its axis. Various heat sources, including electric heating elements, gas burners, or induction coils, load and heat materials within this tube. As the tube rotates, it ensures uniform heating, making it ideal for calcination, sintering, and pyrolysis.

Now, let’s explore how these remarkable furnaces contribute to environmental sustainability.

Energy Efficiency and Reduced Emissions

One of the standout features of this furnaces is their exceptional energy efficiency. Unlike traditional batch furnaces, rotary tube furnaces operate continuously, heating materials. This continuous operation minimizes heat loss during loading and unloading, resulting in significant energy savings.

Lower Carbon Footprint

Additionally, the efficient combustion systems used in rotary tube furnaces help reduce carbon emissions. Advanced controls and combustion technology design modern furnaces, which optimize fuel consumption and minimize greenhouse gas emissions. This reduced carbon footprint aligns with global efforts to combat climate change.

Waste Minimization and Resource Conservation

This furnaces are also champions for waste minimization and resource conservation. Here’s how they contribute:

-

Precise Temperature Control

These furnaces offer precise temperature control, ensuring that materials are heated to the exact temperature required for the desired process. This accuracy reduces the likelihood of overheating or underheating, minimizing material waste.

-

Recycling and Reuse

In many industries, rotary tube furnaces enable the recycling and reuse of materials that would otherwise be discarded as waste. By reprocessing materials, businesses can reduce their reliance on virgin resources and minimize the environmental impact of mining and extraction.

-

Improved Product Quality

Another crucial aspect of this furnaces is their ability to enhance product quality. High-temperature processes carried out in these furnaces often result in superior product characteristics.

-

Enhanced Purity

The high-purity environment inside rotary tube furnaces is essential for the electronics and semiconductor manufacturing industries. The controlled atmosphere and minimal contamination ensure the production of high-quality, defect-free materials.

-

Consistency and Uniformity

The tube’s continuous rotation ensures uniform heating and consistent product quality. This consistency is vital in industries such as ceramics, where temperature variations can lead to defects in the final product.

-

Versatility and Adaptability

These furnaces are not limited to a single industry or application. Their versatility makes them invaluable across various sectors, from pharmaceuticals to aerospace.

-

Diverse Applications

These furnaces accommodate various materials, including powders, granules, and bulk solids. They are used for drying, calcination, roasting, and more, making them a versatile choice for multiple industries.

-

Research and Development

Rotary tube furnaces are crucial in testing new materials and processes in research and development. Their adaptability allows scientists and engineers to experiment with different parameters and achieve precise results.

Conclusion

In conclusion, rotary tube furnaces have emerged as powerful allies in the quest for environmental sustainability. Their energy efficiency, waste minimization, improved product quality, and versatility make them indispensable in modern industrial processes. As businesses prioritize eco-friendly practices, rotary tube furnaces are shining examples of technology that meets industry needs and contributes to a greener future.

If you decide to implement it in your workplace, then ‘Precision Control’ is always the best choice. We provide the best service for rotary tube furnaces in Dubai and Riyadh.

For more information about ‘Precons’,

♥ Do call 9840930370 or Fill out our Appointment form to get in touch!

♥ Follow our Social Media pages for recent updates. Facebook | Instagram