Effective Project Management in the Indian Furnace Industries

Real-World Examples Delivering high-quality furnace projects in India requires effective project management practices. Here are some tailored best practices with real-world examples: 1. Compliance and Safety: Bharat Forge Ltd., a leading manufacturer of forging components, partnered with a project management firm that ensured strict adherence to BIS standards and OSHA guidelines during a furnace […]

Forecasting Of Steel Market Statistics and Visualizations

To complement the previous analysis, here are some statistics and graphical representations to further illustrate the potential impact of the mentioned keywords on steel stocks and business scenarios: War and Conflict: Defence spending in Israel will increase by 5-10% in 2024, potentially benefiting regional construction and infrastructure companies. European steel imports from […]

The Steel Rollercoaster: Navigating Price Fluctuations in Precision Furnace Manufacturing

The past year has been a thrilling ride for the steel industry, resembling a rollercoaster more than a steady climb. Unprecedented price surges followed by sudden dips have left manufacturers, particularly those in the precision furnace industry, grappling with uncertainty and the need for agility. Let’s buckle up and look at the current landscape, its […]

What Industries Benefit The Most From Bogie Hearth Furnaces?

Bogie Hearth Furnaces When it comes to industrial manufacturing, accuracy and efficiency are essential. One technology that stands out in meeting these demands is the bogie hearth furnace. These versatile furnaces have applications in various industries, providing tailored solutions to specific manufacturing needs. Let’s delve into the diverse industries that benefit the most from using […]

Latest Advancements in Industrial Furnaces Technology

Introduction In the dynamic landscape of industrial processes, staying abreast of the latest technological advancements is paramount to enhancing efficiency, productivity, and sustainability. Industrial furnaces, pivotal to numerous manufacturing operations, have witnessed a transformative evolution. In this article, we delve into the cutting-edge developments that define the present and future of industrial furnace technology. […]

Rainy Season Protection Guide for Industrial Furnaces

In industrial operations, the impact of the rainy season on equipment, particularly industrial furnaces, cannot be underestimated. As a trusted partner in industrial excellence, we recognize the critical need to shield these vital assets from the adverse effects of inclement weather. In this comprehensive guide, we unveil proactive measures and strategic approaches to protect industrial […]

Essential Of Pit Type Furnaces In Small-Scale Industries

Pit Type Furnace In industrial heating solutions, pit type furnaces have garnered increased attention for their versatility and efficiency. This article aims to delve into the nuances of pit type furnaces and explore their suitability for small-scale industries. Definition and Mechanism Pit type furnaces are specialized heating systems designed to accommodate a variety of […]

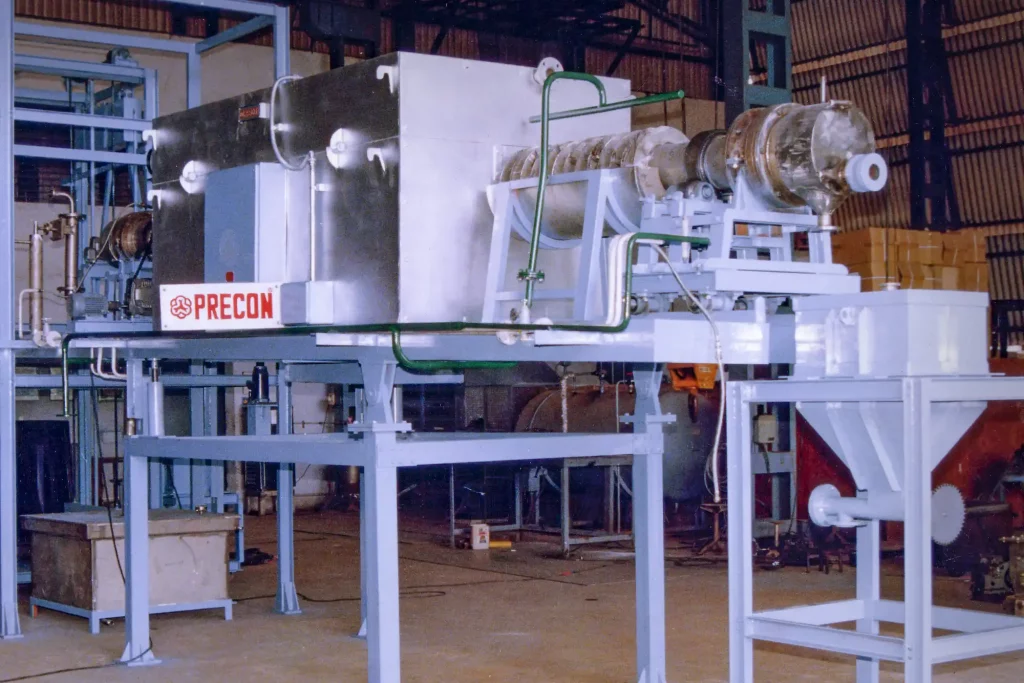

Role of Rotary Tube Furnaces in Environmental Sustainability

In pursuing a greener and more sustainable world, industries constantly seek innovative solutions to reduce their environmental footprint. The rotary tube furnace is a remarkable technology making significant strides. This versatile and highly efficient furnace is pivotal in various industrial processes, contributing significantly to environmental sustainability. This comprehensive article delves into how rotary tube furnaces […]

Benefits of Using a Roller Hearth Furnaces

Roller Hearth Furnace Innovation and efficiency are essential for maintaining competitiveness in the dynamic world of manufacturing. One of the remarkable advancements in this domain is the adoption of roller hearth furnaces. These versatile industrial furnaces have revolutionized various manufacturing processes by offering a range of advantages that contribute to improved productivity, quality, and cost-effectiveness. […]

Bogie Hearth Furnaces for High-Temperature Materials Processing

In high-temperature material processing, selecting the right furnace is paramount to achieving precision, efficiency, and optimal results. Among the various options available, Bogie Hearth Furnaces is the ultimate choice for discerning industries and manufacturers. This comprehensive guide delves into the exceptional features and advantages that set Bogie Hearth Furnaces apart, highlighting their indispensability for seamless […]